BIOMASS AND BIOFUELS

More efficient and more cost effective process for producing biofuels, in particular bioalcohol, using hydrodynamic flow trough cavitation.

- a process for the extraction of carbohydrates from biomass using hydrodynamic cavitation; and

- a process for converting the carbohydrates into bioalcohol using hydrodynamic cavitation.

The present invention uses hydrodynamic cavitation for processing heterogeneous and homogeneous liquid systems. The cavitation facilitates synthesis of intermediate and final products in the overall production of biofuels.

Alcoholic biofuels (or bioalcohol), such as methanol, ethanol, butanol, propanol, etc., may be derived from biological materials, i.e., biomass. The biomass may include corn cob, corn stover, cotton stalk, wheat straw, rice straw, sugarcane bagasse, switchgrass, poplar wood, sorghum straw, and/or water hyacinth. CT's patented Nano cavitation reactor is highly versatile for the extraction of carbohydrates from ligno-cellulosic biomass (or the biomass pretreatment), which is an important and cost-intensive step in the synthesis of (alcoholic) biofuels, especially through the fermentation (or biochemical) route.

CT's patented Nano cavitation reactor is highly versatile for the extraction of carbohydrates from ligno-cellulosic biomass (or the biomass pretreatment), which is an important and cost-intensive step in the synthesis of (alcoholic) biofuels, especially through the fermentation (or biochemical) route.

Hydrodynamic cavitation is useful in the pretreatment of biomass prior to synthesis of biofuels – primarily through fermentation.

Such processing enhances the release of carbohydrates or sugars from biomass prior to fermentation of hydrolyzate (comprising of hexose and pentose sugars).

A large portion of the carbohydrates are extracted from the biomass by an acid or alkali hydrolysis process, which process is aided by the hydrodynamic cavitation.

Strong microturbulence generated by hydrodynamic cavitation helps in the faster and more efficient transport of sugar moieties out of the biomass matrix into the solution.

The Nano cavitation device is particularly efficient at mixing the biomass with reagents and generating in this mixture the transient cavitation features followed by separation of the reaction mixture comprised of the extracted carbohydrates, residual initial reagents, remaining biomass, and other by-products.

Constant refreshing of the water in the biomass matrix enhances the rate of hydrolysis due to the fresh supply of hydrolyzing ions inside the biomass matrix and also dissolution of sugar and carbohydrate molecules leading to enhanced yield. The shock waves generated by microbubbles also help in expanding or swelling of biomass that increases the net voidage of the matrix allowing for, smoother flow of liquid medium or water through the matrix.

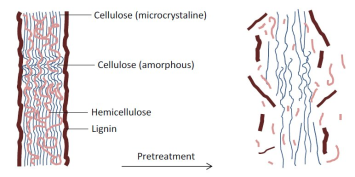

These pretreatments are applied prior to the enzymatic hydrolysis of cellulose in the biomass. The pretreatment has a two-fold purpose: (1) to break down the shield formed by lignin and emicellulose which results in better andhigher accessibility of enzymes to the cellulose during enzyme hydrolysis; and (2) to reduce the degree of polymerization of cellulose with disruption of crystalline structure, which enhances the yield of the enzymatic hydrolysis. The ligno-cellulosic biomass is typically in the form of agro- or forest residue.

These pretreatments are applied prior to the enzymatic hydrolysis of cellulose in the biomass. The pretreatment has a two-fold purpose: (1) to break down the shield formed by lignin and emicellulose which results in better andhigher accessibility of enzymes to the cellulose during enzyme hydrolysis; and (2) to reduce the degree of polymerization of cellulose with disruption of crystalline structure, which enhances the yield of the enzymatic hydrolysis. The ligno-cellulosic biomass is typically in the form of agro- or forest residue.

Biomass pretreatment is perhaps the most cost intensive step in overall biofuels synthesis. Obviously, any advancement of the pretreatment technology would have a significant impact on the economics of biofuels.

Process

A process for extracting carbohydrates from biomass, comprising the steps of: preparing the biomass for extraction of carbohydrates; forming a first biomass solution comprising the prepared biomass, water, and acid or an alkali; subjecting the first biomass solution to a first Nano cavitation treatment, wherein acid or alkali hydrolysis of the biomass occurs; filtering the first biomass solution into a first filtrate and an intermediate biomass, wherein the first filtrate contains extracted carbohydrates; creating a second biomass solution comprising the intermediate biomass, water and an enzyme source; exposing the second biomass solution to a second hydrodynamic cavitation treatment, wherein enzymatic hydrolysis of the biomass occurs; filtering the second biomass solution into a second filtrate and a filtered biomass, wherein the second filtrate contains extracted carbohydrates. Fermenting the second filtrate to create a bioalcohol and separating the bioalcohol by distillation or similar process. The first and second filtrates may be combined and fermented in a single step.

- Nano cavitation treatment, wherein acid or alkali hydrolysis of the biomass occurs;

- A second hydrodynamic cavitation treatment, wherein enzymatic hydrolysis of the biomass occurs;

Test

After cavitation of corn slurry, enzyme was added to the samples and a short 1 hour hydrolysis followed. The treated samples were found to yield 2-3 times more reducing sugar compared to the control (untreated) samples. The study suggests that Cti Nano cavitation systems enhances enzymatic hydrolysis yield, reduces particle size of corn slurry and could be a potential effective pretreatment for corn slurry.

We have done extensive study with cavitation in this particular field and seen substantial improvement up to 35% increase in yield.