Water Treatment

One of the major challenges facing mankind today is to provide clean water to a vast majority of the population around the world. The treatment of wastewater prior to discharge and its reuse have become absolute necessities. CTi put a substantial R&D effort into designing a patent-pending Cavitation & Electrocoagulation System for waste water treatment. In the electrocoagulation process, the coagulant is generated in situ by electrolytic oxidation of an appropriate anode material. The introduced highly charged polymeric metal hydroxide species neutralize the electrostatic charges on suspended solids and oil droplets to facilitate agglomeration and resultant separation from the aqueous phase. The simultaneous action of advanced hydrodynamic nano cavitation, electrocoagulation and active chemical species formed in situ provide a unique synergistic effect resulting in a high-efficiency purification process. The System is capable of removing heavy metals, fats, oil, grease, complex organics, bacteria, viruses and cysts, and suspended and colloidal solids; breaking oil emulsions in water and processing multiple contaminants.

The technology maximizes the reuse of resource materials, slashes transportation and disposal costs, as well as the associated liabilities. Operating costs can be dramatically reduced. The decrease in produced sludge can reach 60% when compared to conventional chemical methods. Other benefits include: low power requirements, low capital and maintenance costs, minimal operator attention, no chemical additions, consistent and reliable results, tolerance to a wide variation in the waste stream and water reuse resulting in a negligible amount of discharge.

The technology maximizes the reuse of resource materials, slashes transportation and disposal costs, as well as the associated liabilities. Operating costs can be dramatically reduced. The decrease in produced sludge can reach 60% when compared to conventional chemical methods. Other benefits include: low power requirements, low capital and maintenance costs, minimal operator attention, no chemical additions, consistent and reliable results, tolerance to a wide variation in the waste stream and water reuse resulting in a negligible amount of discharge.

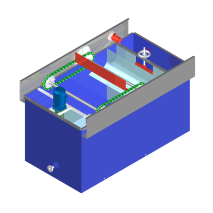

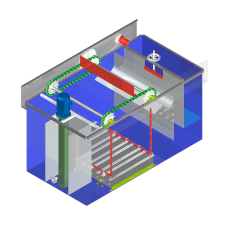

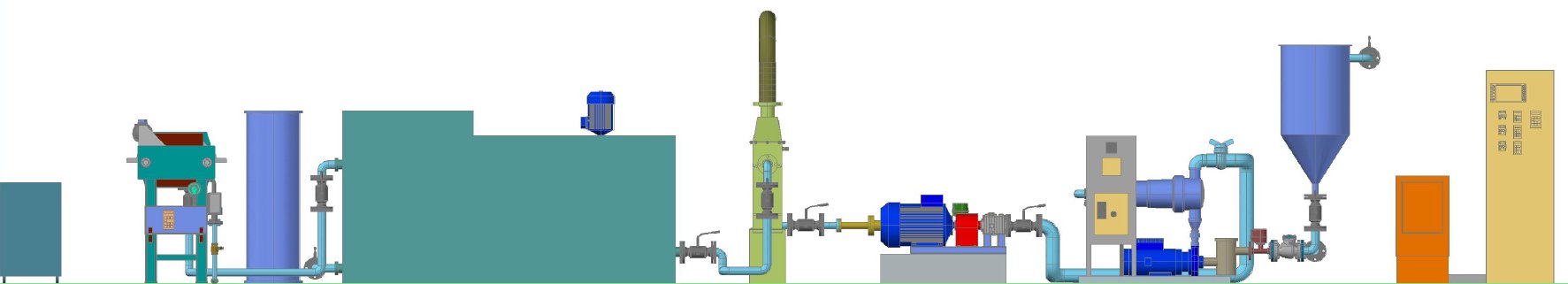

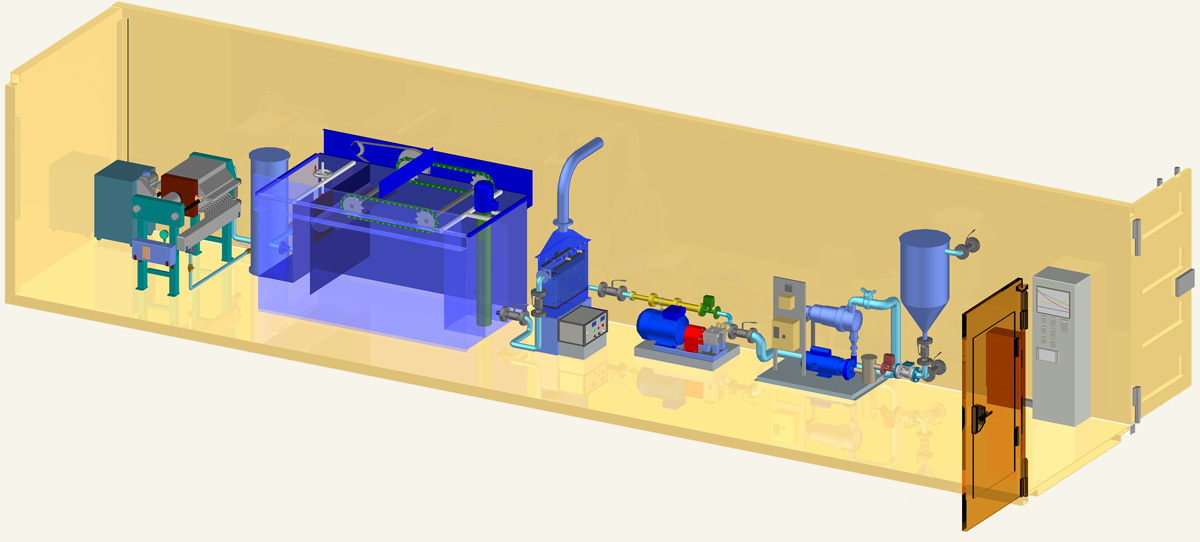

![]() CTI Water Treatment Process

CTI Water Treatment Process![]() Cavigulation Water Treatment Technology

Cavigulation Water Treatment Technology

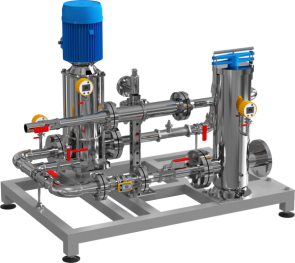

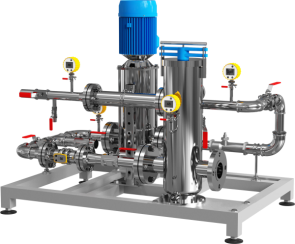

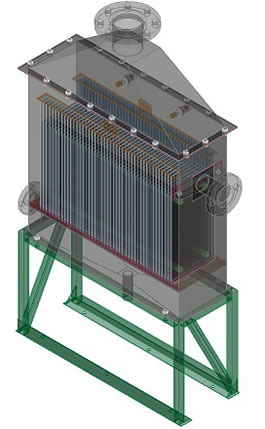

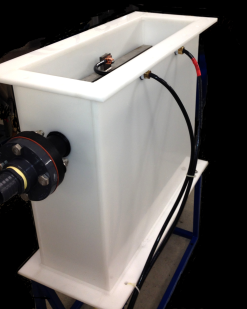

"ECO- ONE" ELECTROCOAUGALATION UNIT DESIGNED BY CTI

Titanium Electrodes + Non Sacrificial Anodes + Proprietary Coating

Capacity 1500 gal/hour to 2100 gal/hour per unit. 5700 liter/hour to 7500 liter/hour

Dimensions (L*W*H), mm - 740*270*1100

Anode life is 5 to 10 years. The tank is made from Polypropylene rust and chemical resistant material.

A rectifier is an electrical device that converts alternating current (AC) to direct current (DC). Available with remote controlled PC.

"ECO - PLUS" ELECTRO FLOTATION AND SKIMMER SYSTEM

Titanium Electrodes + Non Sacrificial Anodes + Proprietary Coating

Electroflotator "ECO - PLUS 35"

Water Treatment up to 7 m3/hour, Voltage - 30 V. Dimensions (L*W*H), mm - 2500*1300*1300 Equipped with cavitation micro air bubbles generator. The micro air bubble diameter is between 5um---15um. Micro bubbles lift the water suspended solids slowly rising to the upper surface. The micro air bubble will stay in water for about 50-60s.

Advantages:

Big aeration volume, micro air bubble with fast rise speed, simple maintenance, low energy consumption, low noise, long service life, no need for air compressor and dissolved air tank.

System can be applied for water treatment in petroleum, petrifaction, textile, food, papermaking, printing and dyeing, fermenting, tannery, slaughter, industrial water treatment, etc.